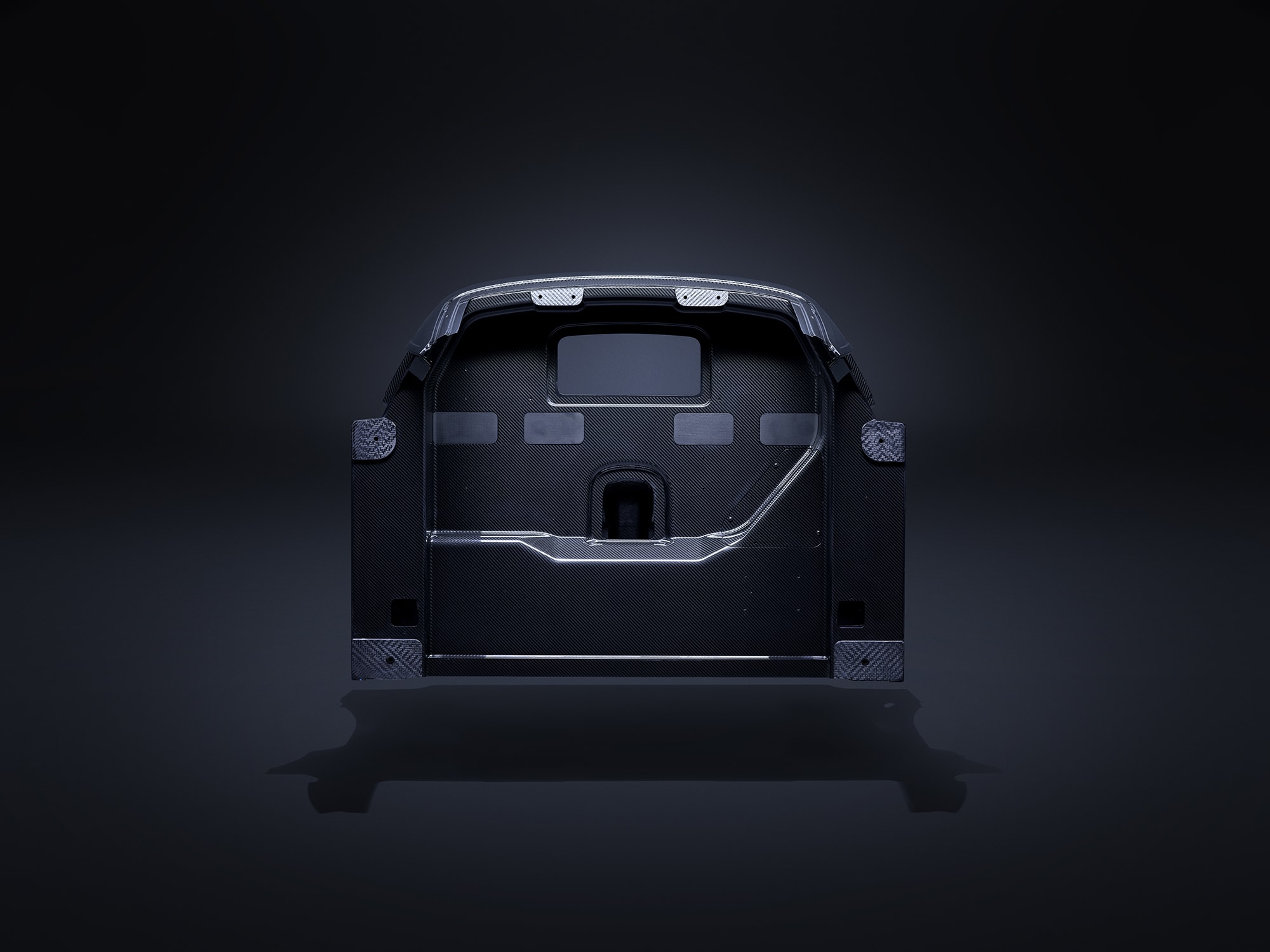

ALL NEW HENNESSEY VENOM F5 CARBON FIBER CHASSIS

DESIGNED & ENGINEERED TO DELIVER 500+ KM/H (310+ MPH) TOP SPEED

Sealy, Texas & Silverstone, England – After an extensive two-year long engineering and development phase, the Hennessey team has done it again. The company has built an all new carbon fiber chassis that will serve as the foundation of the Venom F5.

Built entirely of carbon fiber, the all-new ground-up design has been engineered and built to propel the Venom F5 to a top speed of over 500 kilometers per hour (310.7+ mph). The new F5 chassis is both strong and light weight. Torsional rigidity has been measured at 52,000 newton meters per degree (38,353 lb-ft torque per degree) and the total weight is just 86 kilograms (190 lbs).

“Our all new carbon fiber chassis is an engineering marvel and to see it in person is like looking at a piece of artwork. It’s like a piece of automotive jewelry that’s built to run 500+ km/h,” said company founder and CEO, John Hennessey.

The first three Venom F5’s are currently in production and testing will begin in Q2 2020. The base price for the Venom F5 is $1.8 million and Hennessey is only building a total of 24 examples, 12 for the American market and 12 for international markets. US allocations are close to being sold out. The Venom F5 will make its official debut at

The Quail during Monterey car week in August of this year.

Being mated to the new chassis is Hennessey Specialty Vehicles’ all-new bespoke 1,800+ hp engine called Fury. Based on classic American V8 architecture, the Hennessey Venom F5 engine produces an astounding 1817 horsepower and 1193 lb-ft of torque. It uses a combination of high-tech, lightweight engine components (crankshaft, pistons, connecting rods & custom engine block) that combine for 6.6L of displacement. Combined with a pair of Precision ball bearing twin turbochargers with 3D printed titanium compressor housings, the Venom F5 engine delivers over 1800 bhp at 8000 rpm!

Hennessey Venom F5 Engine Delivers 1817 Horsepower

A Texas-Built Twin Turbo V8 Engine Named “FURY”

Sealy. Texas– After an extensive engineering and development phase, the Hennessey team has done it again. The company’s all new Venom F5 engine produces an astounding 1817 horsepower and 1193 lb-ft of torque. Based on the classic American V8 / LS architecture, the Hennessey V8 engine uses a combination of high-tech, light weight engine components (crankshaft, pistons, connecting rods & custom engine block) that combine for 6.6L of displacement. Combined with a pair of Precision ball bearing twin turbochargers with 3D printed titanium compressor housings, the Venom F5 engine delivers over 1800 bhp at 8000 rpm!

“We exceeded our target horsepower number. Actually, we blew our target number out of the water by delivering over 1,800 horsepower,” said company founder and CEO, John Hennessey. “The F5 engine has a very broad power band with over 1,000 lb-ft of torque available from 2,000 to 8,000 rpm. Give it the full throttle and it’s the most furious engine that we have ever built. Thus, we gave our F5 engine a special name: “Fury.”

“Fury” also incorporates a unique Venom F5 intake manifold design which places the intercooler between the plenum and cylinder heads. This unique design allows the inlet air temperatures coming out of the turbos to be greatly reduced before the charge air goes into the combustion chamber, thus resulting in greater air density and greater overall power efficiency. Rounding out the engine package, “Fury” has a multi-stage dry sump oiling system that keeps Pennzoil 10w60 synthetic motor oil flowing through the heart of the beast at all times and at its 8000 rpm redline.

“This is a very important milestone in the building of our all new Venom F5,” said Hennessey. “With over 1800 bhp and a curb weight of less than 3000 lbs, the Venom F5 will offer the best power to weight ratio on the market. We plan to begin testing our first car later this year.”

Hennessey Venom F5 V8 Engine Specifications:

- Power: 1817 bhp @ 8,000 rpm

- Torque: 1,193 lb-ft @ 5,500 rpm

- Redline: 8,200 rpm

- Displacement 6.6 liter (400 CID)

- Bore: 4.125 in.

- Stroke: 3.750 in.

- Billet aluminum intake manifold with integrated air to water intercooler system

- Forged aluminum pistons (10.0:1 compression ratio) with steel extreme duty wrist pins

- Forged steel light weight H-bean connecting rods

- Extreme duty forged steel connecting rod bolts

- Light weight extreme duty billet steel crankshaft

- Forged steel V8 engine block with billet main caps, increased cylinder wall & deck thickness & 6 bolts per cylinder

- High-flow aluminum cylinder heads with canted titanium intake valves

- Inconel exhaust valves with dual valve springs

- Extreme duty billet steel hydraulic roller camshaft

- Extreme duty hydraulic roller lifters

- Extreme duty billet steel pushrods

- Extreme duty stainless steel shaft mounted rocker arms

- Dailey Engineering 4 Stage billet dry sump oiling system

- Dailey Engineering Billet CNC aluminum oil pan

- Precision ball bearing twin turbochargers (76 mm billet aluminum compressor wheels) rated at 1,350 bhp per turbo, making 23 psi boost pressure at 1,817 bhp

- 3D printed titanium turbo compressor housings

- High-flow twin turbo wastegates

- High-flow twin turbo blow-off valves

- High-flow billet aluminum 90 mm dual throttle bodies

- High-flow fuel injectors, 2 per cylinder

- High-flow stainless steel twin turbo headers with 1 7/8 in. primary tubes

- High-flow stainless steel 3.0 in. twin turbo downpipes

- High-flow catalytic converters

- High-flow 3.5 titanium exhaust system